Fish meal antioxidant TBHQ

As an antioxidant, it must meet the following requirements as much as possible: no harm to the human body; There should be no bad taste, smell, or color; Low concentration can be applied; If added to oil, it is fat soluble and can still maintain effective antioxidant capacity after processing; Need to be fast, effective, and cost-effective

However, the currently allowed antioxidants cannot meet the technical requirements for anti oxidation of all pastry food. Therefore, adding an appropriate amount of antioxidant tert butyl hydroquinone (TBHQ) according to the characteristics of pastry food during the processing is necessary and effective in slowing down the oxidation of oil and fat during the production process, preventing the loss of nutrients and stabilizing color, maintaining the good flavor of the product, and extending the shelf life of the product. Therefore, the necessity of adding antioxidant tert butyl hydroquinone (TBHQ) to baked goods is evident and sufficient.

Pastry and bread stored in the air for a long time are prone to spoilage due to oxidation of their lipid components. The oxidation of oil components not only causes food discoloration, discoloration, destruction of vitamin A, D, E, and other components, but also produces odor. In addition, essential fatty acids such as linoleic acid and linolenic acid in oil are also damaged, reducing the nutritional function of the product. In severe cases, harmful substances such as oxides, peroxides, and decomposition products such as epoxypropylaldehyde can be produced, leading to food poisoning. Adding antioxidant TBHO is a simple, economical, and ideal method to prevent and slow down the loss of nutrients and the generation of odors caused by food oxidation.

The tert butanol method is widely used and can be catalyzed by strong acids such as concentrated sulfuric acid and concentrated phosphoric acid. Both domestic and foreign patent literature have reported this process, such as using toluene or xylene as solvents, the selectivity and yield of this reaction are relatively ideal. In addition, strong acidic ion exchange resins such as D001 and Amberlyst 35, solid acids [5], zeolites [6], and ionic liquids [7] can also be used as catalysts for this reaction, but their catalytic activity is not ideal.

At present, the production of tert butyl hydroquinone both domestically and internationally adopts the tert butylation method of hydroquinone, as shown in Figure 2. According to different classifications of alkylation reagents, it can be divided into tert butyl method, isobutylene method, and MTBE method. Due to the high toxicity of MTBE to human beings and the environment, this method is almost limited to theoretical research in the laboratory and cannot be promoted in industrial applications.

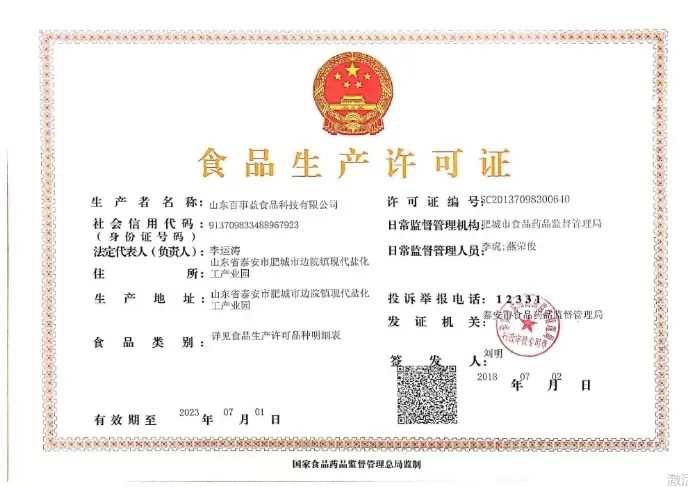

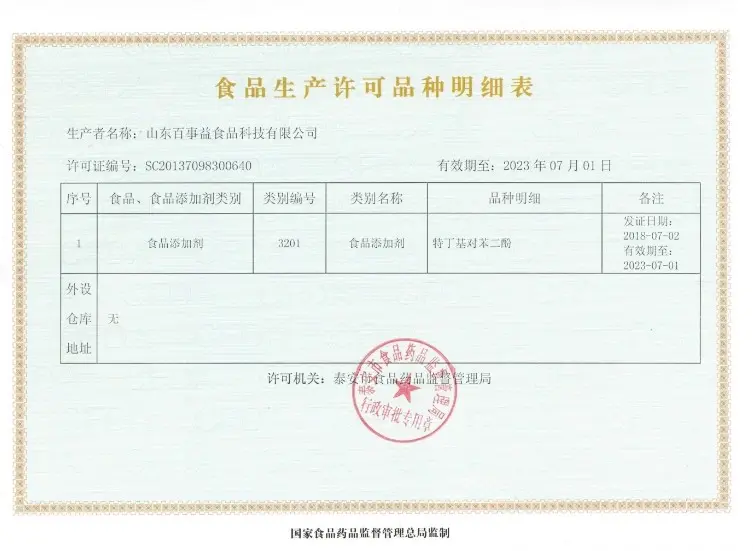

Product standard:

TBHQ, with reference to the U.S. Pharmacopoeia standards for similar products, the country in 2011 unified the formulation of the GB-26403-2011 national standards, which was implemented on May 1, 2011, for our PepsiCo, we developed and produced TBHQ quality is higher than GB-26403-2011